A leading provider of filling & packing machine for many years.

When you want to buy a filling machine, what are you worried about?

High labor cost!

Low production efficiency!

Don’t know how to purchase the right filling machine!Don’t know how to source from China!

How to transport?

How to install?

How to run it?

How to maintain?

How… …

Let us help you!

Which bottles the filling machine is suitable for?

The filling machine is suitable for bottles of various materials, such as glass bottles and plastic bottles. The filling volume ranges from 1ml to 1000ml. It can be customized according to different bottle types, caps, and the specific requirements of customers.

What are the components of a filling machine?

1.Bottle feeding tray, This part is used to transport the bottles to the filling station through the conveyor. Generally suitable for round bottles that have regular shapes and are easy to stand up.According to customer needs, this part is optional, and customers can also choose a bottle unscrambler with a relatively high degree of automation.

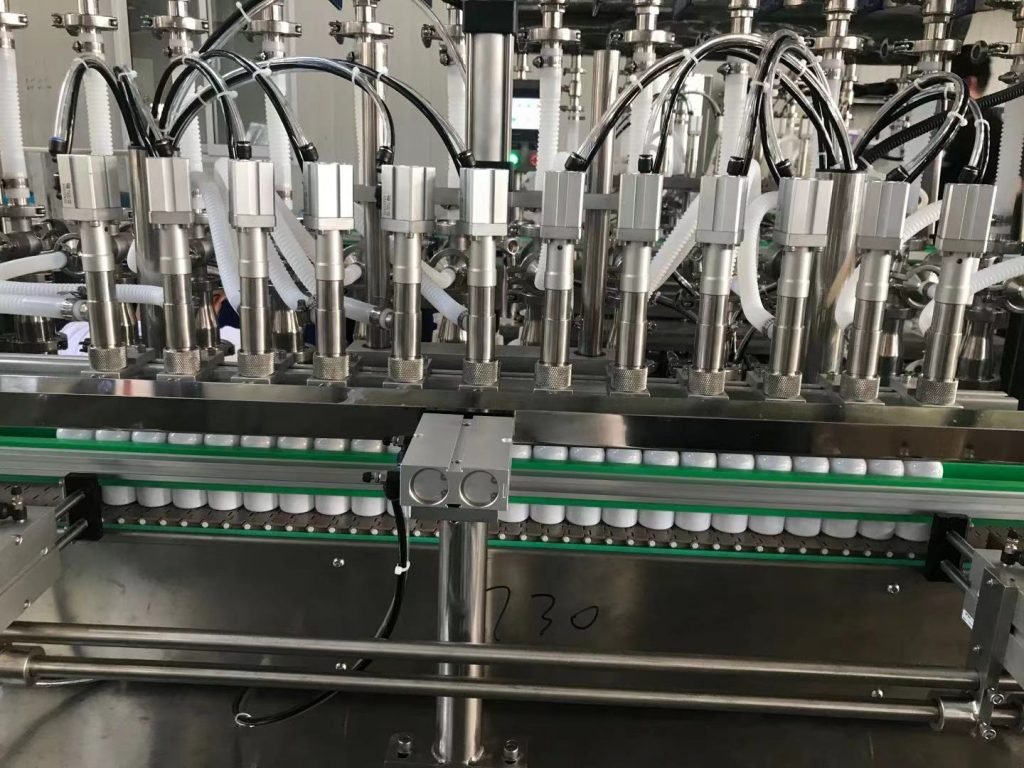

2.The filling part is generally determined to use a plunger pump or a peristaltic pump for filling according to the size of the filling volume and the characteristics of the material, and the number of filling nozzles is determined according to the customer’s requirements for speed.SS304 or SS316 can be selected for the part that contacts the material, if it is corrosive material, Teflon gaskets will be selected.If the liquid is prone to foaming, it will choose to use the servo lift method to fill from the bottom.

3.The third part is the vibrating disk, which is used to arrange the caps. It is operated by vibrating and transports the caps to the cap feeding station through the track. If the size and shape of the caps are different, a different vibrating disk needs to be customized.

4. Screw cap part, this part is composed of screw cap and star wheel. The star wheel is also called index disc, which is used to fix the bottle when capping. If the diameter or shape of the bottle is different, a different star wheel and screw cap part are needed. Generally, a claw-type screw cap head is used, which is suitable for caps of different sizes and does not need to be replaced frequently.If the customer has requirements for the force of the screw cap, the servo motor can be used to control the torque。

Which machines are included in the entire filling line?

Filling and capping is mainly composed of the above 4 parts, but which parts are included in a complete production line?

Filling and capping machine-Labeling machine-Aluminum foil sealing machine- Cartoning machine

These machines can be connected to run, or they can run separately, you can choose according to your needs,Here are just a few typical parts, of course, it can also include other machines, such as sleeve labeling machines, heat shrinking furnaces, etc.

Filling and capping machine

Labeling machine

Aluminum foil sealing machine

Cartoning machine

How ?

How to transport?

When the machine is completed, we will pack the machine in stretch film and plywood boxes, and contact the customer to confirm the forwarding. Customers can choose FOB clause to use their own forwarder, or use our forwarder through CIF clause. Because the machine is relatively large, we generally Transport by sea. Some countries can choose the DDP clause. After the customer has paid the tariff, our freight forwarder is responsible for delivering the machine to the customer’s designated location. For specific information, please contact us for confirmation.

How to install ?

Each machine is fully packaged, customers only need to do some simple installation after receiving the machine.In addition, each production line will be equipped with a tool box, and the customer does not need to purchase additional tools after receiving the machine.

How to run the machine?

After installing the machine, connect it to the power supply and air source, and you can run the machine according to the instructions. The machine is controlled by PLC and touch screen. The operation is simple. If you encounter any problems, you can contact the sales directly. We must be the first time Reply to you.

How do I buy a suitable filling machine ?

In order to help you choose a suitable filling machine, we need to know the following information:

- What material do you want to fill?

- Send us a picture of your bottle and cap.

- What is the filling volume of your bottle?

- What is filling speed do you prefer?

This information can help us customize a suitable machine for you,and it will be better if you could let us know your budget of the machine .