The tube filling machine is used to fill semi-solid products (such as paste, gel, glue, honey, ointment, etc.) for pharmacy, cosmetics, food and chemicals etc., and has a tail sealing function. Seal the tail and cut off the excess part.

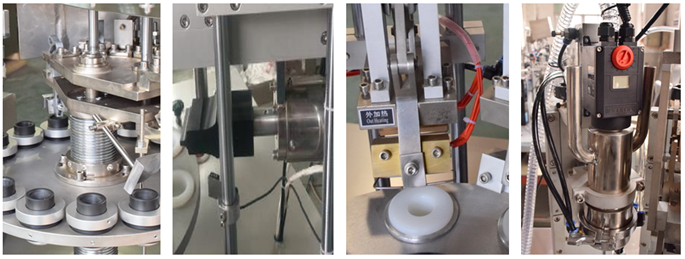

The Tube filling machine is generally suitable for tubes of three materials, Laminated , plastic, and aluminum . Most customers will choose aluminum pipes and plastic tube to use different machines, so as to avoid unnecessary troubles caused by changing molds. Plastic tubes mainly have three sealing methods: copper block, hot air gun and ultrasonic. Copper block heating sealing is generally used for products in the chemical industry that do not have very high requirements on the appearance of the sealing. Hot air guns and ultrasonic sealing are more choices in most cosmetics industries. The speed of the hot air gun is relatively faster than that of the ultrasonic. Because the temperature is high, a chiller is required. Generally, a chiller is included in the quotation. The ultrasonic speed is slightly slower, but the sealing effect is better than that of the hot air gun,and it is easier to change molds for different tube diameters. Customers can choose a suitable filling and sealing machine according to their own requirements.

In addition, the filling machine is also equipped with automatic marking and coding functions, and the coding content can be customized according to customer requirements.

Tell your supplier, your requirements, such as filling volume, tube material, tube diameter, and let them help you choose a suitable tube filling machine.