Different products need different machiners, contact us to get the suitable solution!

Different products need different machiners, contact us to get the suitable solution!

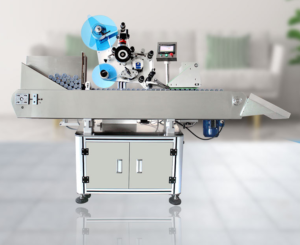

The horizontal labeling machine is suitable for automatic feeding of round bottles that are not stable when conveying while standing.widely used in medicine, cosmetics, electronics, hardware, plastics and other industries;

| Power supply | 220V/240V 50Hz/60Hz |

|---|---|

| Rate | 1.5KW |

| Labeling accuracy | ±1mm |

| Labeling speed | 150~400pcs/min |

| Product size | 1600×650×1450 |

| Air pressure | 0.5~0.6Mpa |

The horizontal labeling machine is suitable for automatic feeding of round bottles that are not stable when conveying while standing. The horizontal conveying method is adopted to increase the stability of conveying and improve the labeling accuracy. The diameter of the conveying rollers and the distance between the rollers can be increased to meet the labeling of products with larger diameters. The taper of the roller can be modified to meet the labeling of small taper bottles

Features of horizontal labeling machine:

◆High speed–horizontal roller conveyor mechanism is adopted, the conveyor chain is inclined, the bottle is automatically guided, and the conveying and labeling is stable. The labeling speed is as high as 100-400 bottles/min, saving a lot of manpower and material resources;

◆Low bottle breaking rate–using flexible bottle separation technology and flexible labeling technology, smooth bottle labeling, and the bottle breaking rate is less than one hundred thousandths;

◆Excellent labeling quality–adopting the tape circumvention and deviation correction technology, the label head and tail have a high degree of overlap; the rolling type labeling, the labeling is flat, without wrinkles, and no bubbles, which improves the packaging quality;

◆High stability– advanced electric control system composed of PLC+touch screen+optical eye+testing label electric eye, which supports 7×24 hours high-speed operation;

◆Intelligent control–automatic photoelectric tracking, with no object but no labeling, no label automatic correction and automatic label detection functions to prevent missing labels and label waste;

◆Sturdy and hygienic–mainly made of stainless steel and high-grade aluminum alloy, in line with GMP production specifications, firm structure, beautiful and generous;

◆With fault alarm function–production counting function, power-saving function, production number setting prompt function, parameter setting protection function, convenient production management;

–Using a stepper motor, the speed is faster and more stable

–Marking electric eye, if there is no label or bottle, the machine will automatically stop running

–It can be adjusted according to the size of the label and bottle to facilitate better positioning of the label and avoid shifting

Optional functions of the automatic horizontal labeling machine:

①Hot coding/printing function;

②Automatic material collection function (combined with product consideration);

③Automatic feeding function (customized according to customer requirements);

Application of the automatic horizontal labeling machine:

◆Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.;

◆Applicable products: small products requiring labels or films to be attached to the circumferential surface or small cone surface;

◆Application industry: widely used in medicine, cosmetics, electronics, hardware, plastics and other industries;

◆Application examples: solid rubber bottle labeling, oral liquid bottle labeling, pen holder labeling, lipstick labeling, medicine bottle labeling Stationery labeling, big pen labeling, marker pen labeling, brush labeling, water-based pen labeling, watercolor pen labeling, small ballpoint pen labeling, correction pen labeling, gel pen labeling, etc.

Contact us for details!

China’s most professional filling and packaging machine experts!

We will contact you within 1 working day, please pay attention to the email with the suffix “@olsenmachinery.com”