Different products need different machiners, contact us to get the suitable solution!

Different products need different machiners, contact us to get the suitable solution!

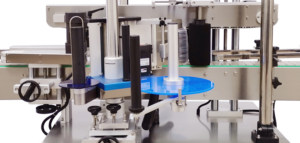

The double-sided labeling machine is suitable for all kinds of flat bottles, square bottles, or round bottles and small arc double-sided or single-sided labelings, such as cosmetics, mineral water, strong wine bottles, laundry liquid flat bottles, beverage square bottles, and lubricating oil. bottle.

| Power supply | 220V/240V 50Hz/60Hz |

|---|---|

| Rate | 1.5KW |

| Applicable label size | Length:20mm~200mm ,width:20mm~160mm |

| Applicable product size | Length:20mm~250mm ,Width:30mm~90mm ,Height:60mm~280mm |

| Labeling accuracy | ±1mm |

| Labeling speed | 150~400pcs/min |

| Product size | 1600×650×1450 |

| Air pressure | 0.5~0.6Mpa |

This automatic double-sided labeling machine is suitable for single-sided and double-sided labeling of flat bottles, special-shaped bottles, and square bottles in daily chemical, household chemicals, medicine, food, and other light industry industries. It is an optional Ribbon coding machine, labeling and printing production batch number, production date, and other information at the same time, to achieve the integration of labeling and coding, reduce packaging procedures, and improve production efficiency. Applicable to self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, two-dimensional code labels, transparent labels, etc. The equipment has high stability, a good labeling effect, no bubbles, no wrinkles, and a labeling accuracy of ±1mm.

Key features of the double-side labeling machine:

–Strong compatibility, the same device can realize single-sided, double-sided and adjacent right-angled surface labeling of multiple types of products (such as: flat bottles, round bottles, square bottles, special-shaped bottles, etc.), and optional round bottle positioning mechanism, Round bottle rolling mechanism, three-sided labeling mechanism;

–Flexible application and simple operation. It can be produced on a single machine or connected to an assembly line; it adopts a double-sided rigid plastic synchronous guide chain to automatically ensure the neutrality of the bottle, which greatly reduces the difficulty of worker operations or assembly line docking; an automatic bottle separation mechanism is configured, and the product enters The spacing is automatically separated before the guiding mechanism to ensure the stability of subsequent bottle guiding, conveying and labeling;

Equipped with a double-labeling mechanism, labeling ensures labeling accuracy, and double-extrusion labeling can effectively eliminate air bubbles and ensure that the head and tail of the label are tightly attached;

–The use of a new type of elastic pressure topping mechanism ensures stable product delivery and effectively eliminates the inherent error of the bottle height;

–Accurate labeling, high stability, using PLC + subdivided stepping motor to drive label delivery, accurate label delivery; using cam brake mechanism, uniform tension, to ensure that the label is tight, reduce label breakage, and ensure accurate label detection; The detour correction mechanism can prevent the label from shifting left and right to ensure the accuracy of the label;

–Using a stepper motor, the speed is faster and more stable

–Marking electric eye, if there is no label or bottle, the machine will automatically stop running

–It can be adjusted according to the size of the label and bottle to facilitate better positioning of the label and avoid shifting

Application of the double-side labeling machine:

–Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, bar codes, etc.

–Applicable products: products that require labels to be affixed to the side plane, the side surface with a large arc, and the circumferential surface.

–Application industry: widely used in cosmetics, daily chemicals, electronics, medicine, hardware, plastics and other industries.

–Application examples: labeling of flat shampoo bottles, labeling of lubricating oil flat bottles, labeling of round shampoo bottles, etc.

Every Olsen machine is customized according to customer requirements, please contact us and tell us your specific requirements, we will recommend the most suitable machine for you!

China’s most professional filling and packaging machine experts!

We will contact you within 1 working day, please pay attention to the email with the suffix “@olsenmachinery.com”