Toothpaste making machine

Toothpaste making machine

As a daily necessity, toothpaste is a consumer product with great demand. As consumers’ demands are becoming more and more refined, the development of the toothpaste market also needs new blood filling! The production of toothpaste has also become a concern of many manufacturers.

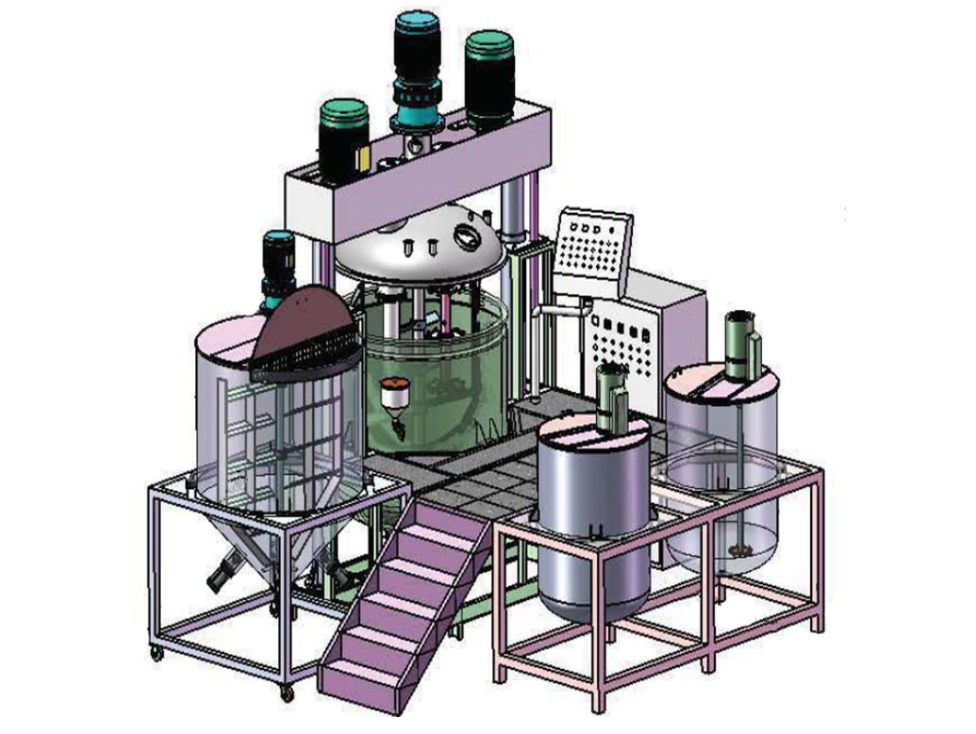

When making toothpaste, according to the toothpaste processing technology ingredients, the raw materials are put into the paste making pot through the pipeline, and the various types of raw materials in the pot are completely dispersed with each other through the super-strong stirring, dispersing, and grinding functions of the paste making machine Mix and vacuum again to remove the foam and become a toothpaste paste. In the paste-making system, all containers and equipment parts that come into contact with raw materials and semi-finished products are made of stainless steel. The design of a high-quality paste-making machine will take into account different needs from production, while a mature design requires years of accumulation and updating of production and design experience.

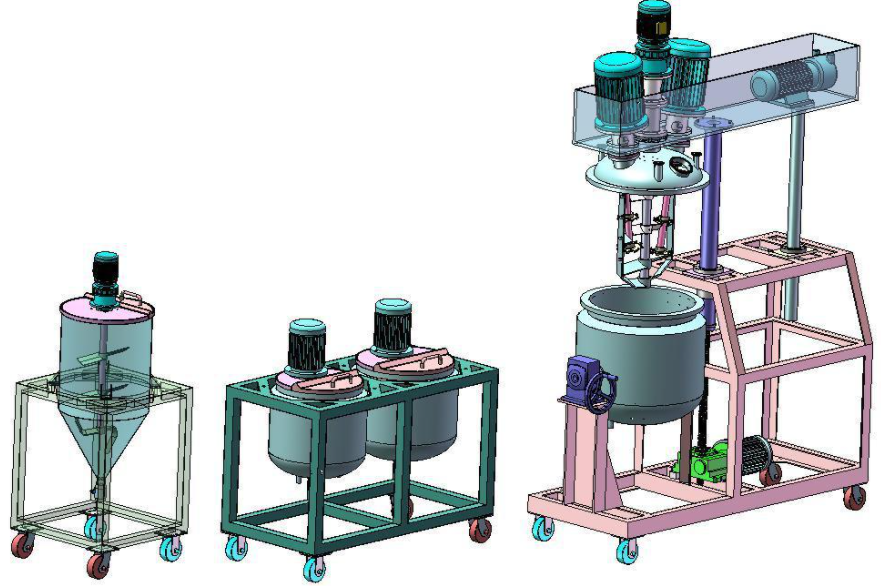

Olsen’s toothpaste making machine is a mature equipment in the toothpaste production equipment link. According to the characteristics of the large proportion of powder in the toothpaste production process, a cone-shaped powder pretreatment pot for powder processing is specially set up, and the main pot is stirred at the same time. The dispersion form is also specially designed. The combination of biaxial high-speed dispersion and anchor or paddle stirring ensures the uniform mixing of powder and other materials. Our mixing system adopts central mixing, which is composed of dispersing discs, all-round high-speed mixing and dispersing, so that materials do not accumulate and dead ends, and can efficiently make materials uniform and delicate.

The tank body is mechanically sealed, and the material processing is operated under vacuum. The vacuum degree can reach -0.095Mpa. The material has a significant deaeration effect. It ensures that the physical and chemical indicators of each pot of toothpaste are consistent, so that each of your toothpastes can do well. , More detailed parameters, welcome to consult olsen.

Related Products

After the paste-making process is over, the finished paste can be transferred to the filling and sealing equipment through a storage tank or a pipeline pump. The next step is to choose the filling and sealing equipment for toothpaste. Traditional toothpaste uses aluminum tubes. and with the advancement of environmental protection, most modern toothpastes uses the composite tube, generally aluminum-plastic tube packaging. According to the container of toothpaste packaging, such as “composite tube, metal tube, and plastic tube”, The toothpaste production line is equipped with filling and sealing equipment. Customers can also choose equipment with different degrees of automation according to the output and investment budget.

Explore more information

As an industrial equipment supplier, Olsen machinery can design, manufacture, install, and debug various non-standard equipment according to the specific process requirements of customers. It can meet the production of toothpaste on various scales. We are your trusted partner.

Contact us and tell us your needs!