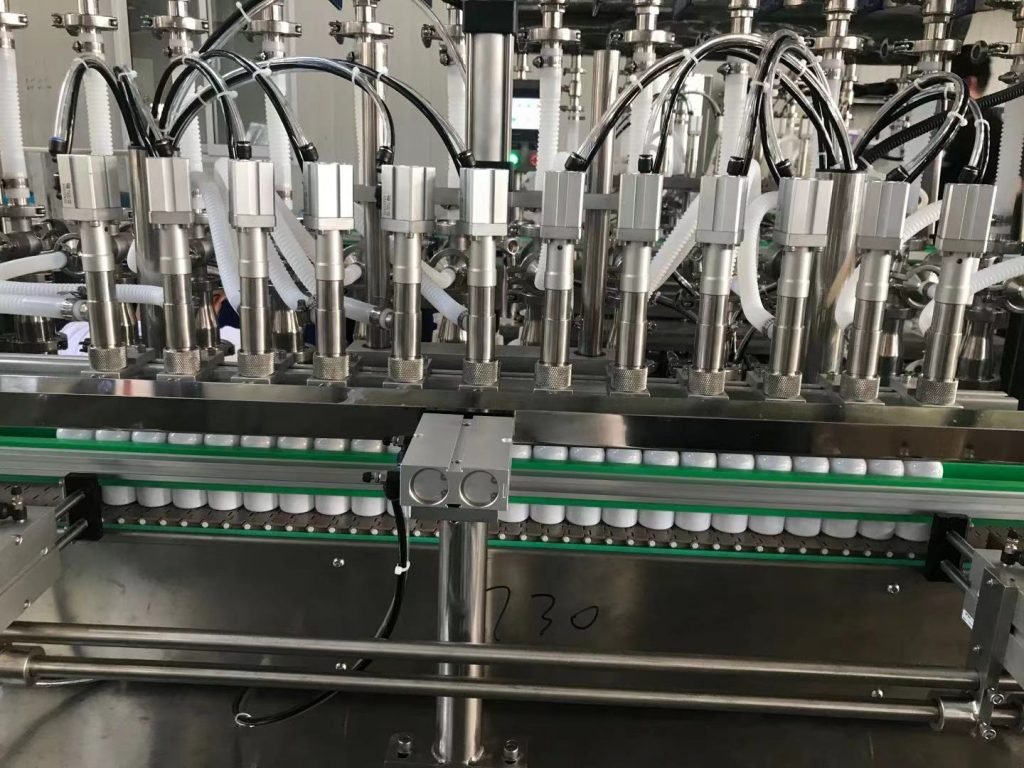

filling machines, whether semi-automatic or fully automatic, according to different request of the client , such as the filling speed , use different quantity pumps for each fill head on the machine. The pump assists in moving liquid through the product pathway and in to waiting container, making the machine a good solution for thicker, or less free-flowing, liquids. The appropriate pump will be selected according to the characteristics of the material. Generally, the plunger pump is used for viscous materials and pastes, and the peristaltic pump is used for small doses of liquid materials.

A time based fill on these machines simply allows the pump to run for a pre-set amount of time each cycle. Simple timers or a PLC will assist operators in setting the necessary times, and pump speed may be adjusted for more accurate fills as well . As the bottles are released into the filling area, a sensor sees the bottles and will automatically begin the filling process by actuating the filling machine.When the filling time has elapsed, it will automatically releases the filled bottles to travel downstream on the conveyor and then releases a new batch of bottles into the filling area to be filled.

The filling line is generally determined according to the customer’s packaging materials and materials. If there are many shapes and types of bottles, it is recommended that customers choose a linear production line, which can reduce costs, reduce the time for mold replacement, and avoid the machine caused by mold replacement. Damage, affecting the production schedule.

In general, the entire filling line can include bottle feeding device, filling machine, capping machine, inkjet printer, labeling machine, cartoning machine, etc. Various additional packaging machines can be configured according to customer requirements. Each part has a separate operating program, which can be combined at will.The whole line only needs 2~3 workers operations.

In the modern era of rapid economic development, labor costs continue to rise, market demand continues to grow, and people’s requirements for automation are getting higher and higher. Small and medium-sized enterprises can choose suitable filling machinery according to their own production capacity and inform suppliers of specific requirements For example, filling materials, filling volume, filling speed, pictures of bottles and caps, the more detailed the information, the more helpful the supplier will customize the suitable machine for you